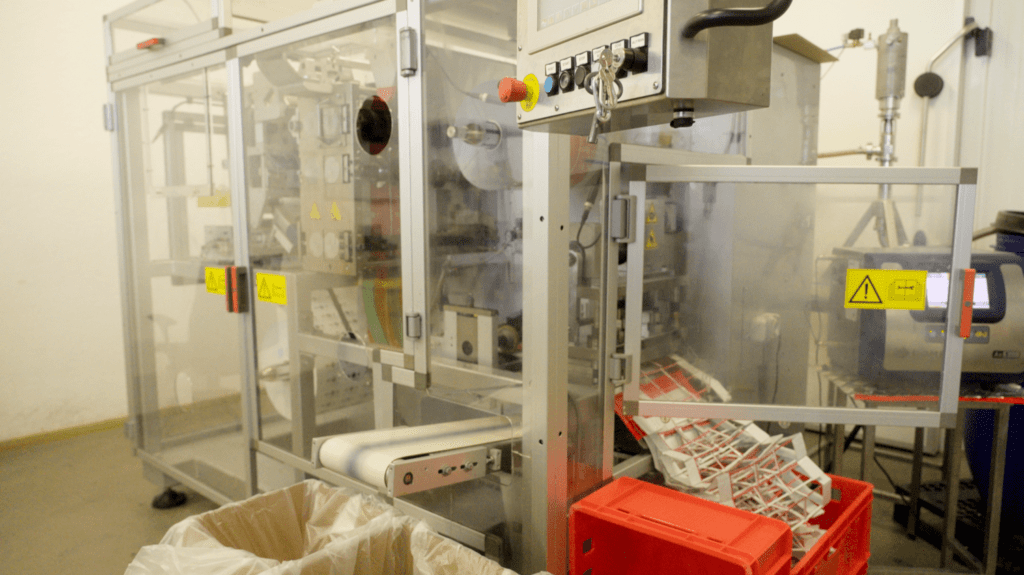

Our factory

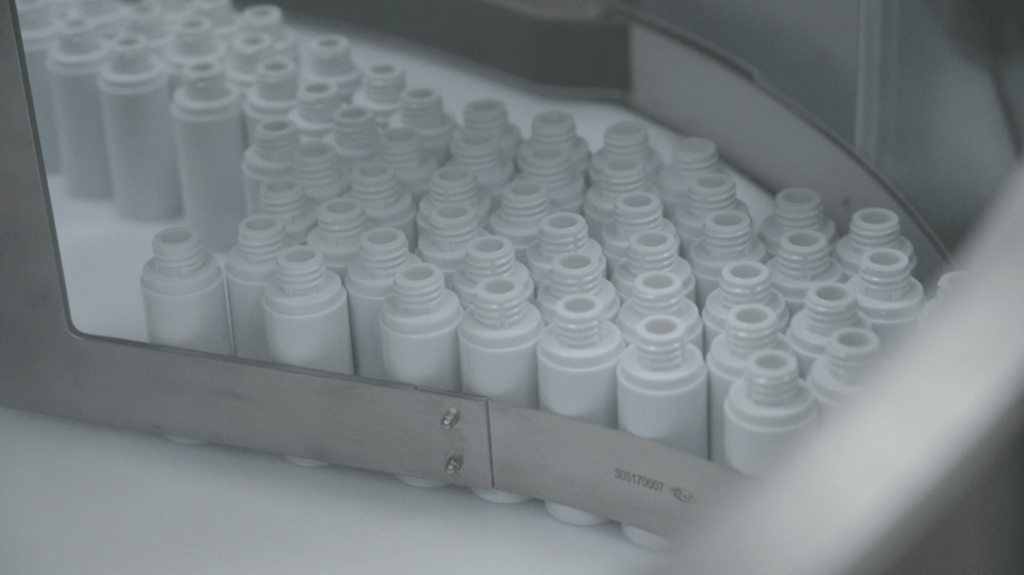

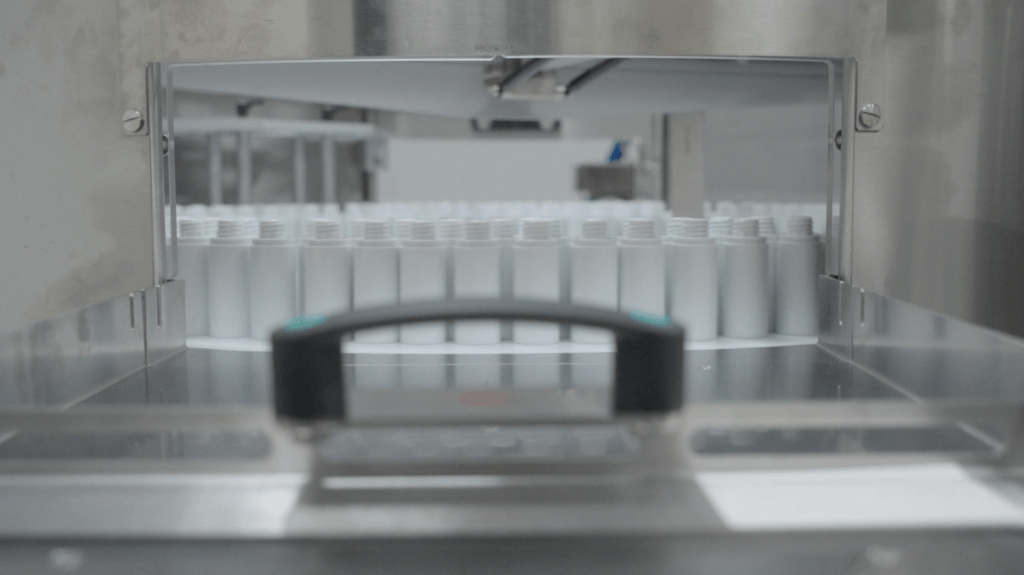

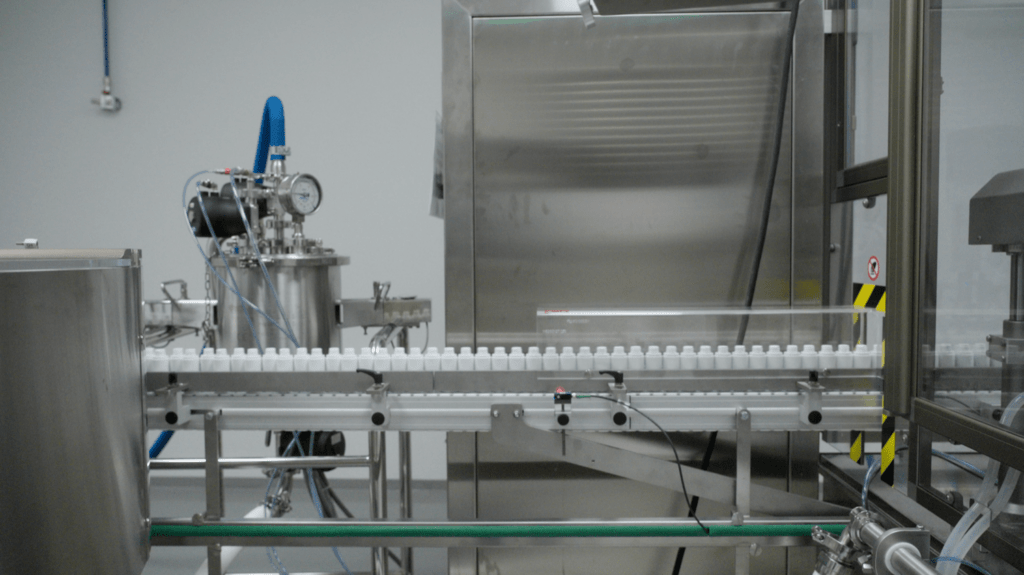

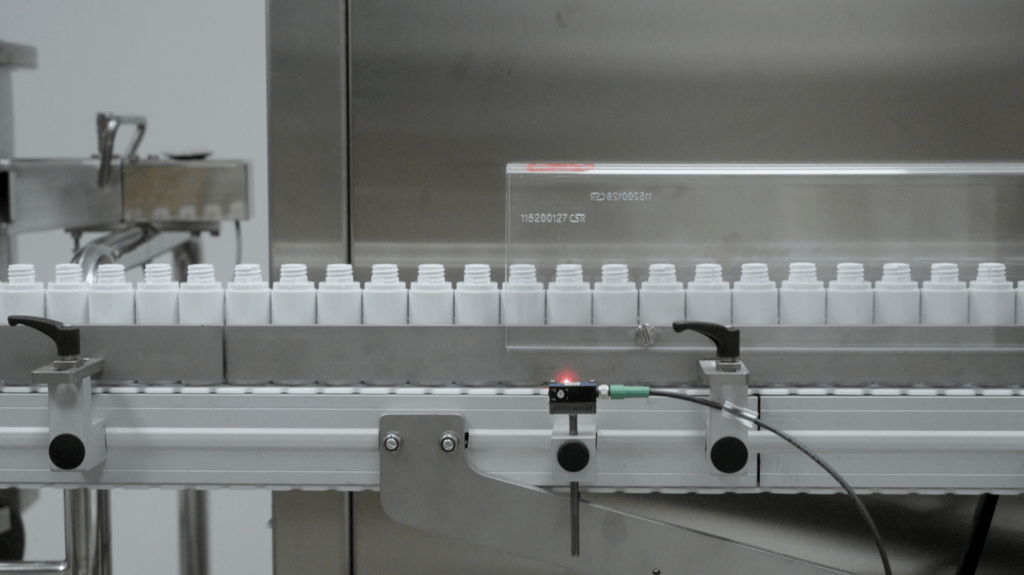

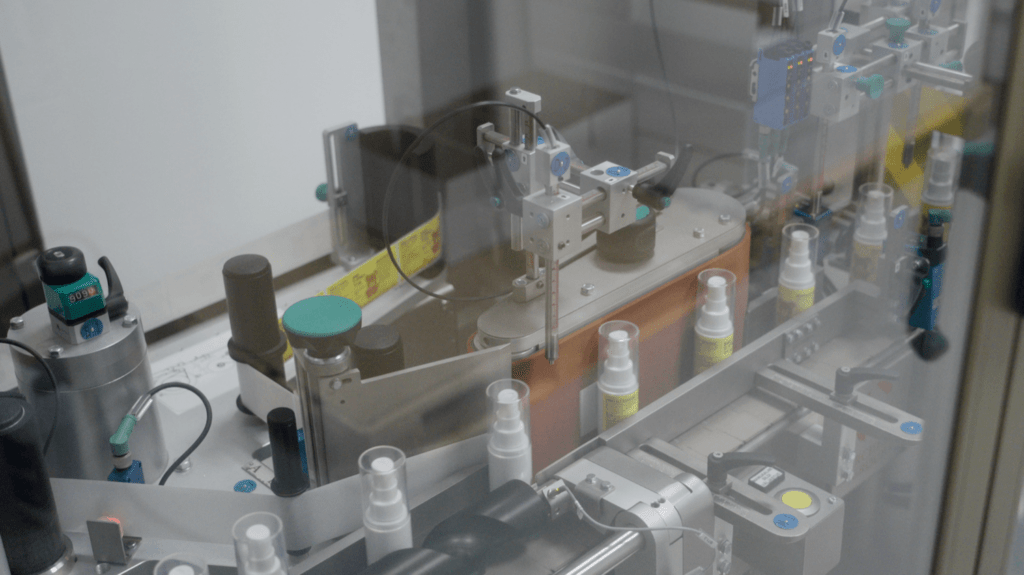

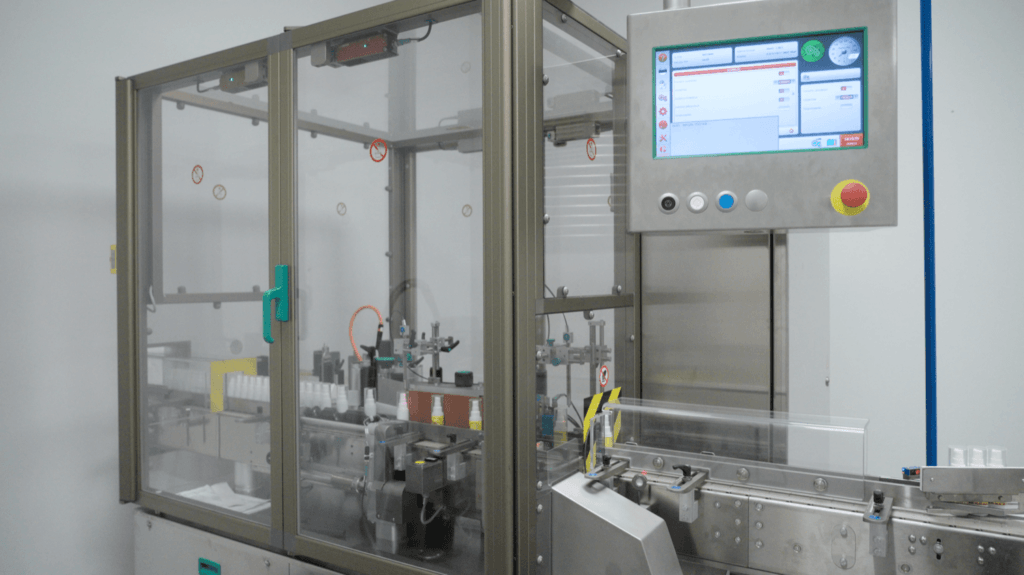

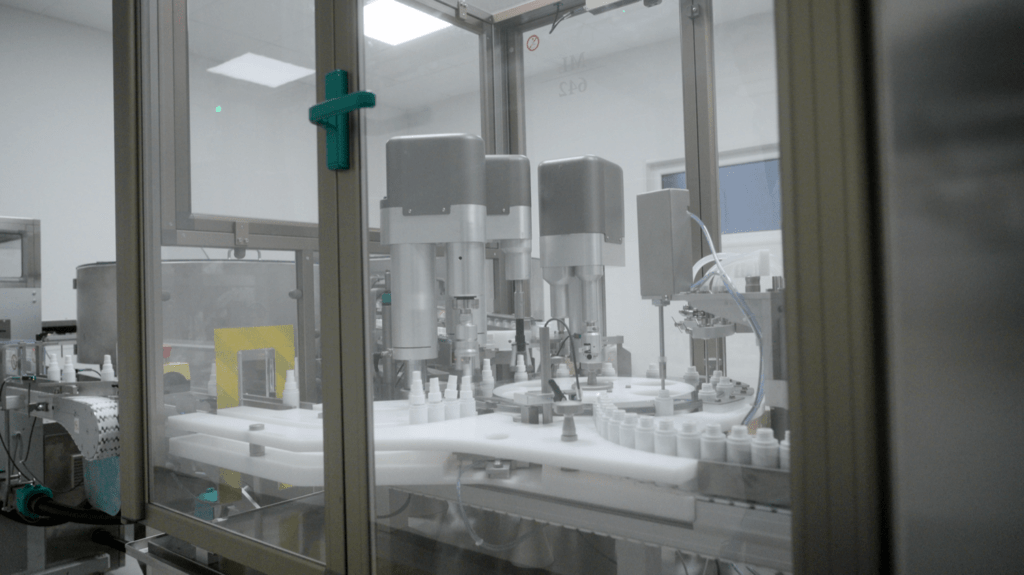

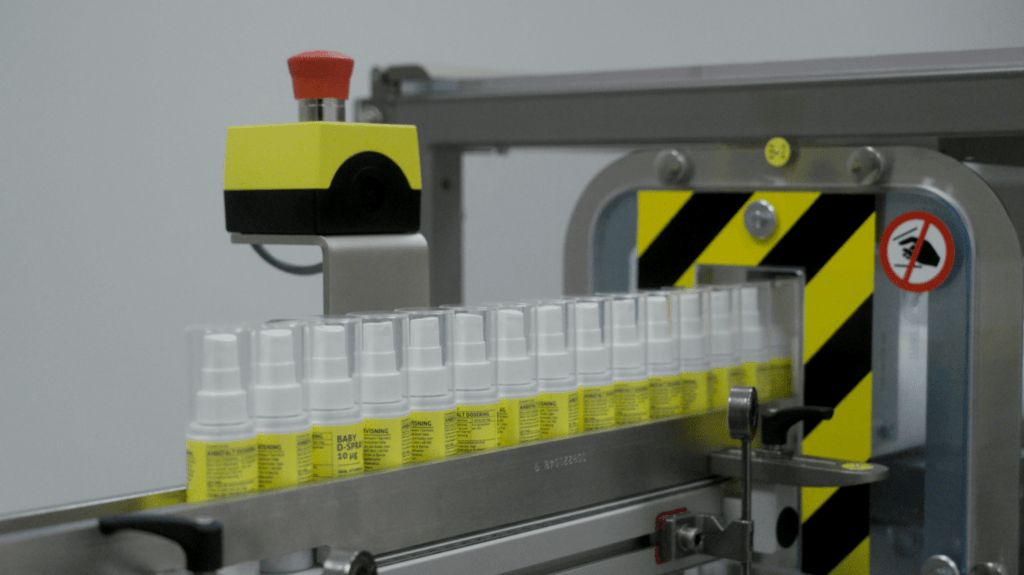

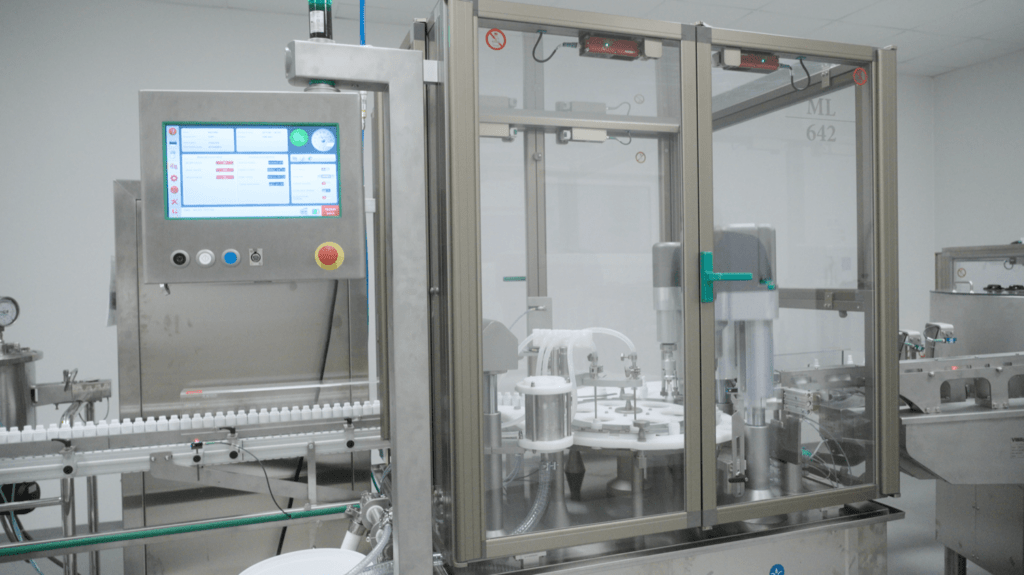

Nordaid Ltd has opened a brand new full-automatic factory for producing liquid food supplements and nutrients. The factory contains up-to-date and high quality production facilities that are GMP and HACCP certified:

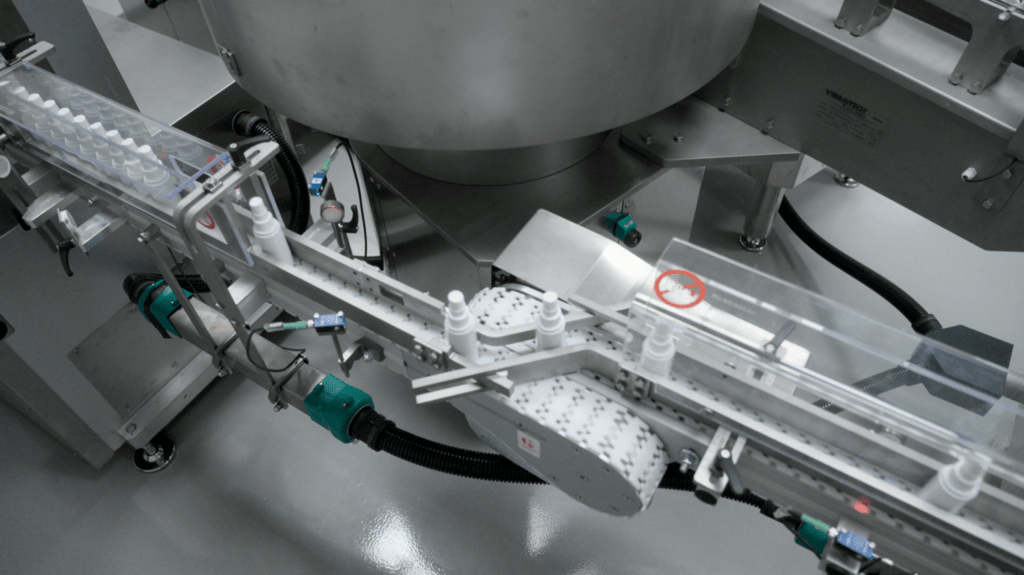

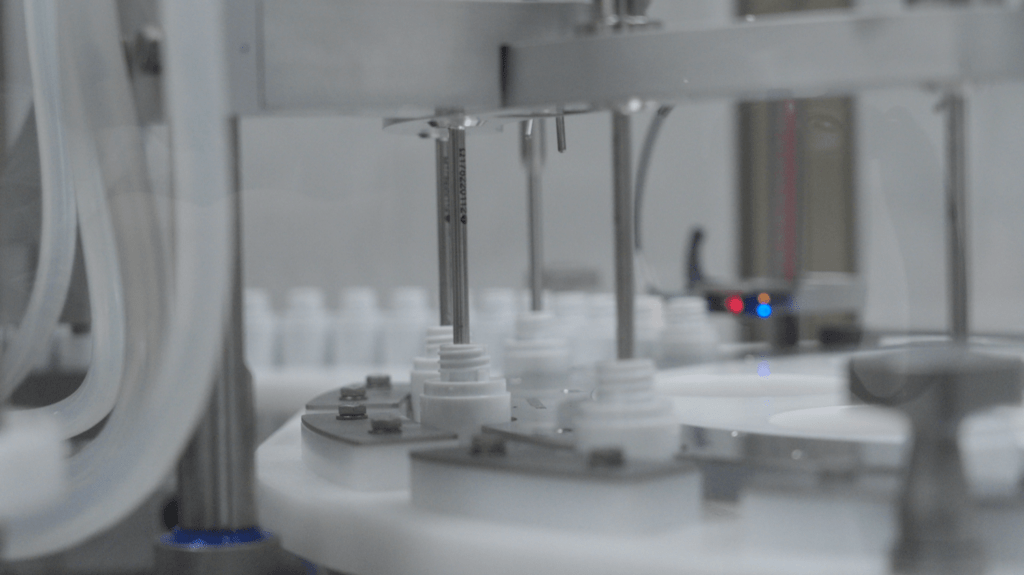

- Our filling line is capable of filling 1000-2500 bottles an hour, depending on the bottle size (up to 500ml).

- The range of product viscosity is broad as produced liquids can be as viscous as honey.

- For mixing capacity we have several mixing tanks with a total volume of 1500l.

- For production we use vacuum, pressure, homogenization and temperature from 8-80 degrees.

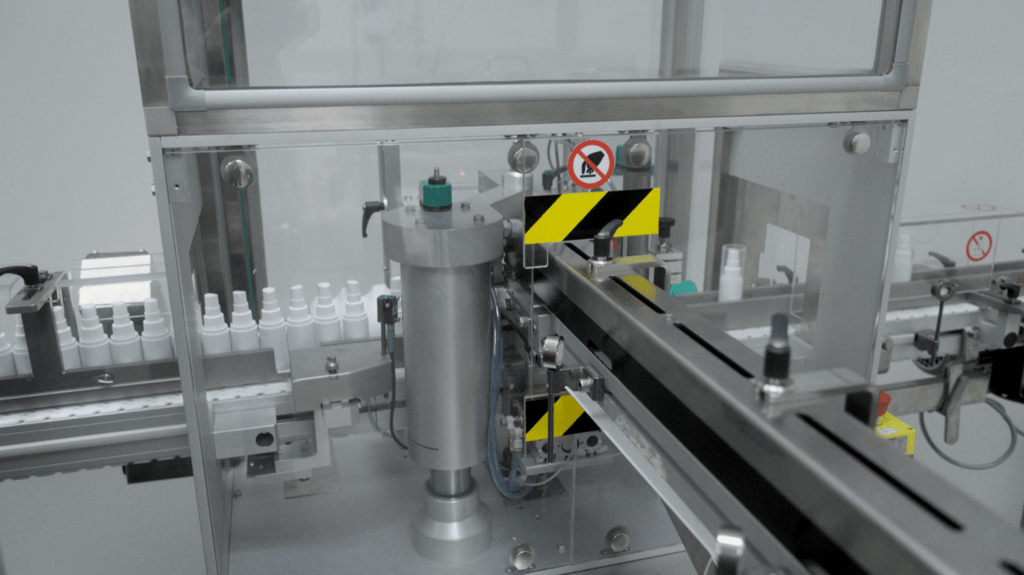

- Highest quality standard – production complies with internationally recognized Good Manufacturing Practice requirements.

- Continuous control – the entire production process, from raw materials to the final product, is strictly monitored and documented.

- Traceability – every batch is fully traceable, ensuring transparency and reliability.

- Consistent quality – products meet the same high standard every single time.

- International recognition – the GMP certificate is accepted worldwide, confirming compliance with global norms.

- Customer trust – our partners and consumers can be confident that the products are safe and of premium quality.

- Professional manufacturing environment – staff training, hygiene, and equipment cleanliness meet the strictest requirements.

- Support for innovation – the GMP framework allows us to introduce new products with the assurance that they are always controlled and high-quality.